Driving Efficiency in Potato Production: How CSS Farms Uses HarvestEye!

Industry

Potato

The Challenge

Large scale potato production demands efficiency, but traditional manual sizing methods were slow, inconsistent, and labour intensive. CSS Farms needed a smarter way to improve accuracy and streamline their tuber sizing and sorting processes.

Results

With HarvestEye, CSS Farms now captures more accurate and reliable sizing data from larger sample sizes, reducing variability and improving decision-making. The system has also streamlined operations by cutting down manual work and providing instant insights through the web portal, supporting both daily efficiency and long-term planning.

Key Product

HarvestEye 2.0, HarvestEye Handheld

“Sizing information is much more accurate and reliable with HarvestEye since the sample size is so much larger than manual sizing methods”

Wayne Jarecki

Farm Manager

“If someone is looking for easy and accurate size data I would definitely recommend looking at HarvestEye”

Wayne Jarecki

Farm Manager

.webp?width=474&height=474&name=OIP%20(2).webp)

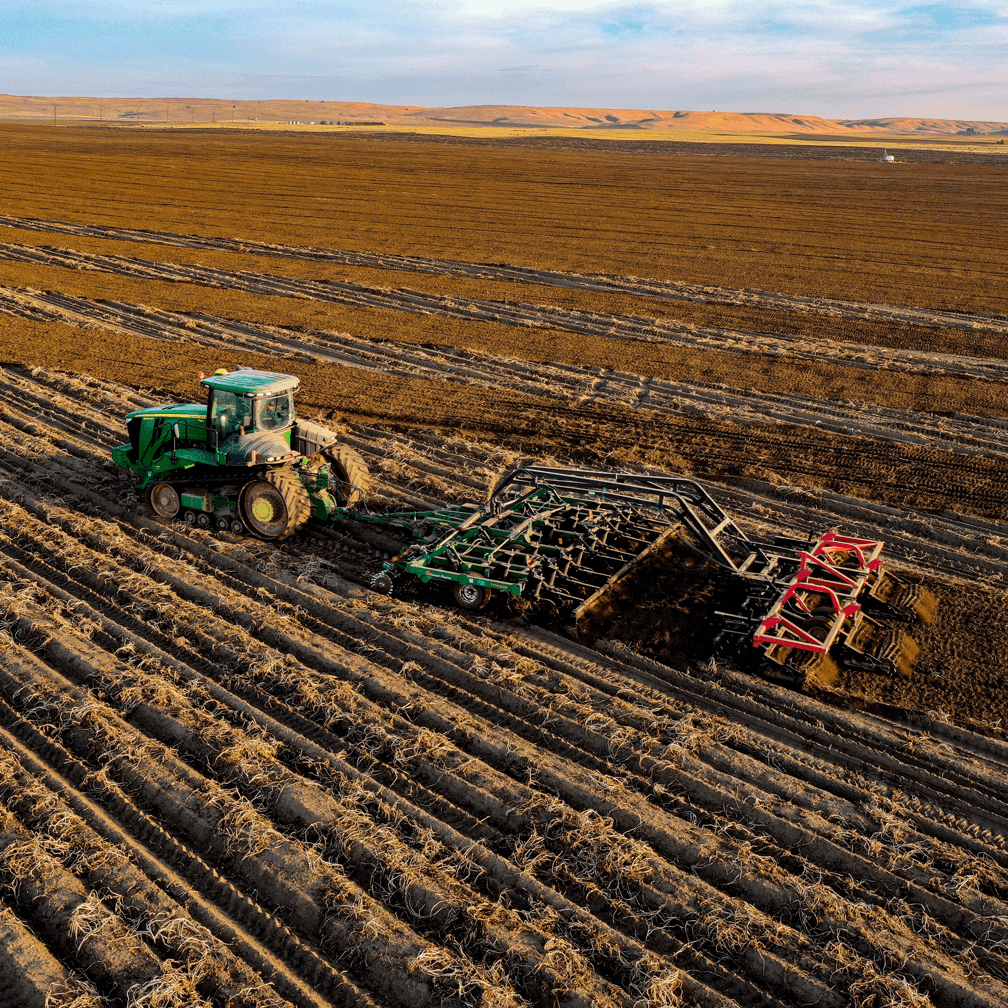

About CSS Farms

CSS Farms, founded by the Carter and Spevak families in Watertown, South Dakota, has grown into one of the nation’s leading potato producers. Operating 17 farms across 10 states, the company specializes in seed, chip, and Table-Stock potatoes, with a reputation for innovation, efficiency, and high-quality supply. Always looking for ways to improve operations, CSS Farms turned to HarvestEye to enhance their tuber sizing and sorting processes.

The Challenge

Efficiency is critical in large-scale potato production, where daily activities such as tuber sizing and sorting can significantly impact yield, quality, and operational costs. Traditional sizing methods often rely on manual sampling, which can be time-consuming and prone to variability. This creates challenges in maintaining consistency, reducing inefficiencies, and meeting customer requirements at scale.

CSS Farms are always looking for ways to improve operations, CSS Farms turned to HarvestEye to enhance their tuber sizing and sorting processes.

The Solution

To address the need for greater efficiency and consistency in tuber sizing, HarvestEye offered CSS Farms a practical way to bridge the gap between traditional methods and the demands of large-scale production. By fitting seamlessly onto existing equipment, the system unlocked new layers of operational insight without disrupting established workflows. Rather than relying on small, time-consuming manual samples, CSS Farms could now capture and analyze data continuously throughout harvest, giving them the clarity and control needed to streamline processes and adapt quickly to customer requirements.

The Results

By adopting HarvestEye, CSS Farms has gained access to sizing information that is far more accurate and reliable than traditional manual methods, thanks to the much larger sample sizes the system can process. This improvement has reduced variability, given the team greater confidence in their data, and allowed them to make better-informed decisions about sorting and supply. Beyond accuracy, the technology has also helped streamline operations by cutting down on time-intensive manual sizing, creating efficiencies that support their large-scale farming model. With data instantly available through the HarvestEye web portal, CSS Farms now benefits from faster, clearer insights that strengthen both day-to-day operations and long-term planning.

They explained how HarvestEye is simple to integrate. It’s just a matter of finding the right physical location on the existing equipment, and then the information is readily available and easy to find on the HarvestEye web portal.